Company fined £1.275m after man crushed to death

A company in Birmingham has been fined £1,275,000 after a 26-year-old man was crushed to death during maintenance work at Mountsorrel Quarry in Leicestershire.

Luke Branston, from Leicester, died in the early hours of 21 June 2017 after becoming trapped between a conveyor and a feed hopper.

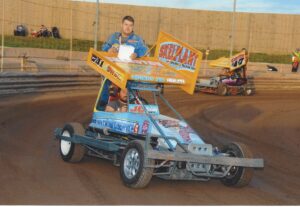

Luke’s family, who loved going stock car racing with him every weekend, say they are devastated by his passing.

The contractor, working on behalf of Branston Site Services Limited, was part of a nightshift maintenance team that was repairing a feed hopper at the Loughborough quarry, operated by Tarmac Aggregates Limited.

He had been stood on a conveyor that was located under the feed hopper and had not been effectively isolated – through cutting the power – before the repair work started.

The conveyor was then inadvertently switched on, trapping Luke against the feed hopper, fatally crushing the 26-year-old.

A Health and Safety Executive (HSE) investigation into this incident found Tarmac Aggregates Limited had failed to ensure the feed hopper was properly isolated before the repair work commenced. The test button on the conveyor electrical panel was not connected to the test circuit and was therefore inoperative. This issue appears to have existed for many years before the incident, meaning Tarmac Aggregates Limited failed to ensure critical defects were recorded and rectified in a timely manner. The company should have also provided a visual and audible pre-start alarm for the conveyor.

HSE guidance can be found at: Quarries – HSE and Provision and Use of Work Equipment Regulations 1998 (PUWER) (hse.gov.uk).

Michael Branston, Luke’s brother, said: “I’m definitely not the same person that I was before this incident, I used to be fun and highly motivated, but now I look at things a lot differently and approach things with more caution.

“I always think the worst all the time in situations and I find myself visualising what would happen if I lost a loved one.

“Luke wasn’t just my brother, he was my best friend, there with me every step of the way, so the loss was massive for me.”

Sharon Branston, Luke’s mum, said: “I feel this has made us an emotional family, having guilty feelings for being happy. We are still here and he is not. Six years on, I still have hard days and cry over silly things. I still have Luke’s ashes at home as I can’t bear the thought of leaving him.

“Every day I think about Luke and wish he was here still, but I only have memories and photos, that’s all we have left.”

Kevin Branston, Luke’s dad, said: “We had to sell Luke’s house to help with money pressure. The loss of Luke’s house hurt a lot, it was as if I was losing a memory.

“Luke was the youngest child of my four children. Luke is like a missing link in my life – at work and more as we loved going stock car racing as a family every weekend. Luke’s racing took him all over the country. Every bit of spare time he had was spent in the workshop fixing his cars with his brother Micky. I go in the workshop now and find myself just sitting there getting upset looking at his race car, thinking why him?

“Sometimes I feel guilty for still being here when Luke’s not. I miss him all the time.”

Tarmac Aggregates Limited, of Trinity Park, Bickenhill Lane, Birmingham, pleaded guilty to breaching Section 2(1) and Section 3(1) of the Health and Safety at Work etc. Act 1974. The company was fined £1,275,000 and ordered to pay £200,000 in costs at Leicester Crown Court on 27 September 2023.

HSE inspector Adrian Jurg said: “This is a devastating tragedy that claimed the life of a young man. Luke’s family have made clear the impact his passing has had on their lives and our thoughts remain with them.

“When a company like Tarmac profit from the hard work of contractors like Luke then the very least they owe him and his family is a duty to ensure he gets home safe at the end of his shift.

“Companies should be aware that HSE will not hesitate to take appropriate enforcement action against those that fall below the required standards.”

This prosecution was supported by HSE enforcement lawyer Alan Hughes.

Notes to Editors:

- The Health and Safety Executive (HSE) is Britain’s national regulator for workplace health and safety. We seek to prevent work-related death, injury and ill health through regulatory actions that range from influencing behaviours across whole industry sectors through to targeted interventions on individual businesses. These activities are supported by globally recognised scientific expertise. hse.gov.uk

- More about the legislation referred to in this case can be found at: legislation.gov.uk/

- HSE news releases are available at http://press.hse.gov.uk

- Michael, Sharon and Kevin Branston’s statements were presented to the court.